In 1972, Asas Filter was built and started the production for abroad and the Middle East. ASAS is Turkey’s leading Filter manufacturer in producing high quality Filters for the automotive sector through their extensive production line, in two different plants located in Iskenderun and in Adapazari.

ASAŞ Filter is a leading filter manufacturer in its field of the automotive sub-industry sector. ASAŞ product range covers a wide variety of oil, fuel and hydraulic filters, air filters and air dryer cartridges for brake systems for automobiles, commercial vehicles, heavy duty vehicles and industrial applicants with approximately 8000 different products.

The brand is exported to 35 countries; mainly to Germany and France in Europe, Middle East, North Africa and the USA.

ASAS have obtained ISO/TS 16949, made Asas Filter gain the title of “being the first Automotive Sub-industry in its industry in Turkey”., and some other important quality accreditations like ISO/TS 14001 and ISO/TS 18001.

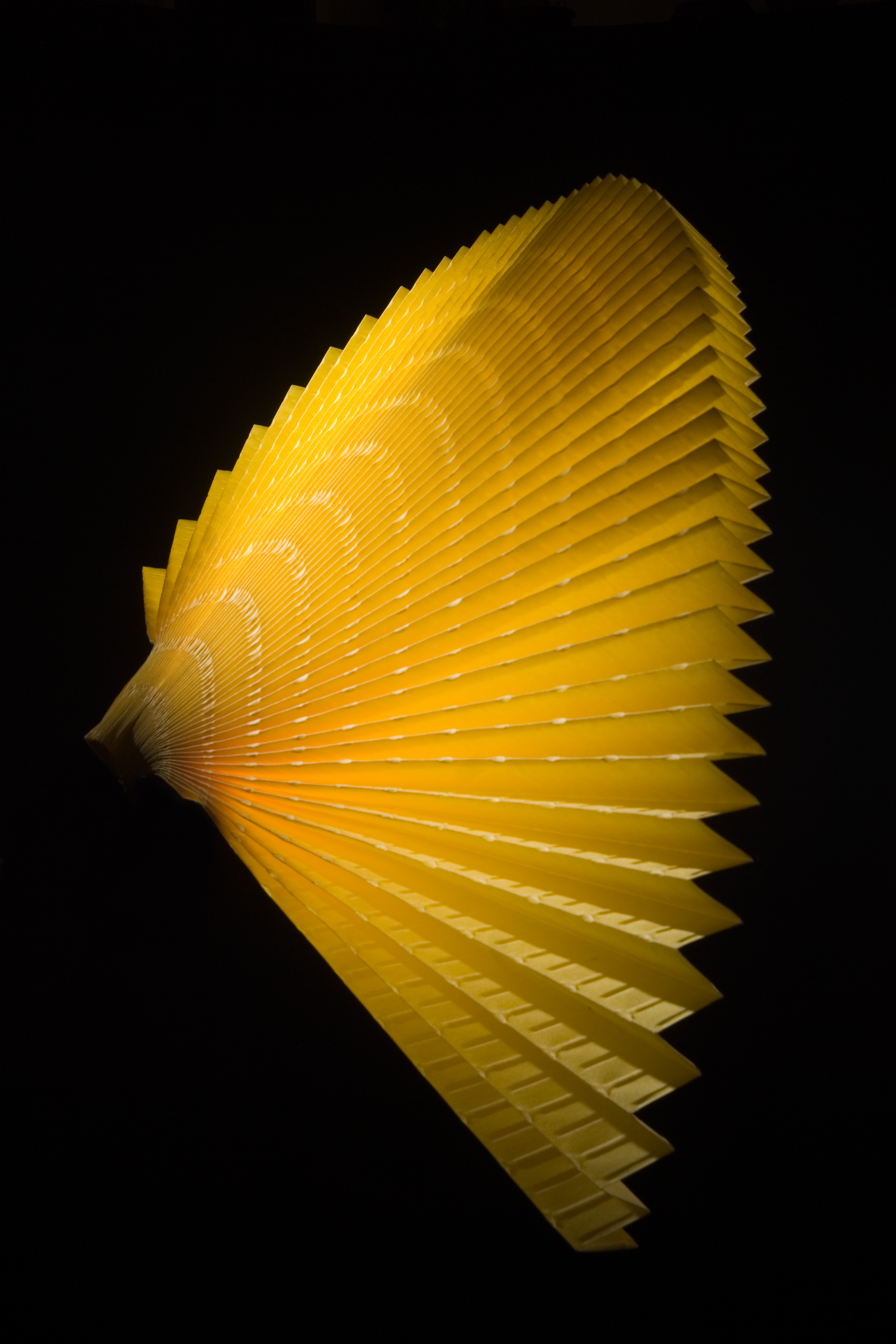

Main row-material suppliers as steel from Ereğli Steel Factory, as high quality paper from H&V - USA, GESSNER - GERMANY and AHLSTROM-ITALY.

ASAŞ Filter produces filters for the most well-known OEM / OES customers in domestic and foreign markets by taking account of customer specific requirements. Some of our clients are Ford, BMC, Isuzu, Kia, Land Rover, Peugeot, Fiat, Hidromek, Komatsu and Citroen.

Some of our Global clients are Scania, DAF Trucks and various International Filter Companies include Bosch, Mahle, Fleetguard and Donaldson.

ASAŞ Filter is a filter expert in Turkey with the laboratory where all the tests can be performed accurately which are confirmed internationally.

Our manufacture which aims inland and especially European markets covers oil, air, fuel and all the other filters that motor vehicles, working machines and industry require.

Our technical stuff who observes new technology in the filter manufacture includes the necessary working machine and equipment to the manufacture by importing or by processing within its facilities regarding with the demands during the implementation of the works. For the time being our daily filter manufacture about being 35-40.000 may increase the number of its shifts depending on the sale programs.

At the same time, polyurethane lidded filters, polyurethane panel filters that are considered as a new concept in the filter industry and pollen filters used in the conditioning systems of the transport are one part of regularly updating manufacture program of our factory.

One of the major factors of our quality is the quality of the products we use in manufacture. Filter paper, our main profit means, is imported from the famous paper manufacturers in Germany and England.

Sheet metal, considered the second profit means and provided by “Ereğli Dəmir Polad” Factory (Ereghli Iron Steel), may also be imported at times due to the difficulties in the provision of the quality and quantity.

Before the filters are brought to the modern control laboratory, filters manufactured in ASAŞ FİLTRE factory are recorded by stuff on the quality provision by testing whether they fit the technical photos of the filters which were published previously. On the basis of the batch, samples in a certain amount obtained from each filter via the sampling method are compelled to the tests on the sustainability verification in the laboratory of quality control in line with the standards below:

- TS7407 and ISO4548 in the oil filters

- TS5395 and ISO4020 in the fuel filters

- TS932 and ISO7750 in the air filters

- BS6410 in the filter papers

EXPERIMENTS IMPLEMENTED IN THE FILTERS

Oil filters

Pressure experiment on the static explosion.

This experiment is carried out in order to determine the maximum static pressure to which the filter resists. In normal conditions, the overall deformation of the filter element is provided by increasing the working pressure 3-4 times on the transport.

Sustainability experiment against increasing heating and pressure.

Filter element 2-3 times is more likely to be subjected to the heating and pressure in the normal conditions within the recorded period, thus it is identified whether any deformation is occurred or not.

Loss of pressure-experiment on inflow features.

This experiment which is conducted in order to specify the reaction that comes from the filter element of the different sized oils, gives essential information on the validity term and features of the filter.

Experiment on obtaining components.

This experiment is mostly applied to the filter elements of which the paper features are unknown, in order to get information on the ability to obtain components with specific micron values of the filter elements.

Experiment on by-pass opening pressure

In case the filter elements are congested and lose their efficiency, this experiment is carried out in order to specify the opening pressure of the by-pass system put into operation. This experiment bears particular importance for the motors.

The by-pass systems which do not work precisely may cause the motor absolutely to collapse.

Experiment on validity term

It is one of the major experiments that are carried out to define the validity term and volume of the filter element.

Fuel filters

All of the experiments conducted for the oil filters are applied to the elements of the fuel filters. But here the experiment conditions are slightly different. The experiment on by-pass opening pressure should not be applied because such system is not available in the fuel filters. Instead of it, the pressure conducted on reducing the resistance by percussive pressure is applied to the fuel filters.

Air filters

There are two types of experiments to be implemented especially for the elements of the air filters

Experiment on reducing the pressure initially

Starting from 10% up to 100%, the following nominal volume of the filter element of the transportation vehicle shows the certain pressure drop to be created. The pressure drop is to be considered in the other parameters and it is the main feature that is required in the filtering ability.

Experiment on the capacity and productivity (fitness)

As it is stated above, the experiments applied to the samples obtained via the sampling method on the basis of the components are considered distorted. However the filters called as Spin-On are experimented on 100% air infiltration against the sheet metal and configuration defects. Applying air pressure between 4-6 bars in this test which was completely conducted without distortion, the filter with distortions in its sheet metal and configuration is automatically removed by testing device.

The filters manufactured in our factory are delivered to the consumers via different channels.

EXPORT

Our export to 40 countries over Europe, North Africa, Middle East, Middle Asia and North America is directly coordinated from the factory. Besides, there are firms that engage in filter trade among our clients, we can enumerate German firms such as MONARK DIESEL, PUROLATOR SCANIA, MAHLE, FLEETGUARD BOSCH, LUBERFINER, FRAM, DAF and American firm GLOBAL SOURCING which we manufacture under their names. At the same time, the manufacture of the components of CKD sent from our factory is implemented in the two configuration lines set in Egypt and kicked off the market.

INTERNAL MARKETING

The gravity is mostly laid on the branches in the internal marketing. Our products are delivered to the consumers through main branches and secondary branches in Istanbul, Iskenderun, Ankara, Izmir, Diyarbakir, Urfa, Bursa, Antalya, Izmit, Samsun, Trabzon, Artvin, Afyon, Konya, but through sales representatives where the branches are not available. Official bodies such as Rural Services, Highways, State Water Company, Gendarme, Fleet, Tank Factories, Turkish State Railways and private subcontract firms such as TEKFEN, NUROL, STFA, ENKA, BAYINDIR İNŞAAT provide internal and external construction places with ASAŞ FİLTRE products whether by tenders or agreement and these filters are commissioned with the service guarantee after each type of quality and sale in the transportation vehicles.

One of the proud sources of the ASAŞ is OPMs.

Companies such as RENAULT, TOFAŞ, PEUGEOT-KARSAN, FORD-OTOSAN, OTOYOL, OTOKAR, ISUZU, ÇELİK MOTOR, HEMA ENDÜSTRİ, BMC, BMC-OMPAŞ, NİSSAN, CHRYSLER, ÇELİK MOTOR-KIA, TEMSA-KOMATSU,SCANIA,DAF,SANGYONG which are considered as the certain manufacturers of our country, use ASAŞ filters by relying on us in the issues of quality, term and relevant prices both in their manufacture and services after sale.

Our factory got a right to obtain ISO-9002 Quality Certificate in1996. Getting the QS-9000 certificate in 2000, ISO 16949 in 2002, ISO 14001, OHSAS 18001 in 2007 the factory threw the first step in its sector.

Our AR-GE department has technical and corporative stuff to design and prepare a new filter to the operation if it is needed. Within this framework, BMC PROFESSİONAL air filters used in the trucks are designed and commissioned by us.